Reed Switches

Search in catalogWhat is a Reed Switch?

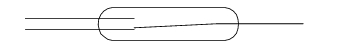

Reed switches are a special kind of electrical switch, actuated (turned on and off or change over) by magnetism. The most common type features two thin, flexible, ferromagnetic metal wires or blades - the reeds - positioned slightly apart in a hermetically sealed glass bubble. These function as the reed switch contacts. It should also be noted that the change-over type has three reeds instead of two.

In most other switch types, contacts are opened or closed by physically manipulating a part of the switch, thus making or breaking the electrical circuit. Typical examples include push-button, momentary or rocker switches - anything that might be described as a solid-state switch.

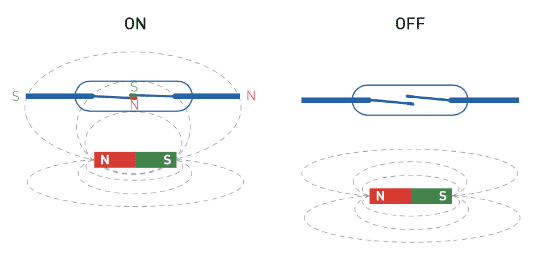

However, reed switches work differently. They are not usually touched at all during actuation. Instead, they rely on magnetic forces to move their contacts together or apart. Depending on the reed switch type you are using (normally open, normally closed or change over), proximity to a magnetic field either opens or closes a small air gap between the two metal blades. In the simplest models, this is often achieved by moving a reed switch magnet closer to - or further away from - the glass envelope housing the reeds.

The magnetic reed switch was invented in 1936 by Walter B. Elwood of Bell Laboratories. Modern versions rely on much the same basic principle as those produced under Elwood’s successful 1941 patent. Today, reed switches are found in a huge range of applications and devices - everything from laptops and mobile phones to key automotive systems, industrial machinery, and security sensors.

The Reed Switch, also known as Reed Contact, is the most economic component for non-touch switching, handling loads from signal load up to 250W in a wide range of applications.

We offer a wide range of reed switches with a glass tube length between 7mm and 50mm.

Switching capacity reaches up to 120 W/VA, switching voltages are between 0 V to 10 KV AC/DC, and switching currents are between 0A to 3A AC/DC.

All switches are available in the following forms:

- normally closed (NC)

- normally open (NO)

- bistable.

How does a Reed Switch work?

A Reed Switch consists of a pair of ferromagnetic reeds, overlapping at their free ends (contact area) at a very small distance and hermetically sealed in a glass tube. The contact area is plated with contact material such as Ruthenium or Rhodium. In presence of a magnetic field the reeds become magnetized the opposite polarity, thus attracting each other and closing contact.

Life Expectancy

The life expectancy of a Reed Switch is about 105…106 switching cycles with maximum power. With a low load the life expectancy can reach 5×108 operations.

The mechanical life expectancy can reach at least 109 operations.

Through the switching of inductive, capacitive and lamp loads, the life expectancy is considerably reduced due to exceeding the specified maximum current.

Capacitive Loads

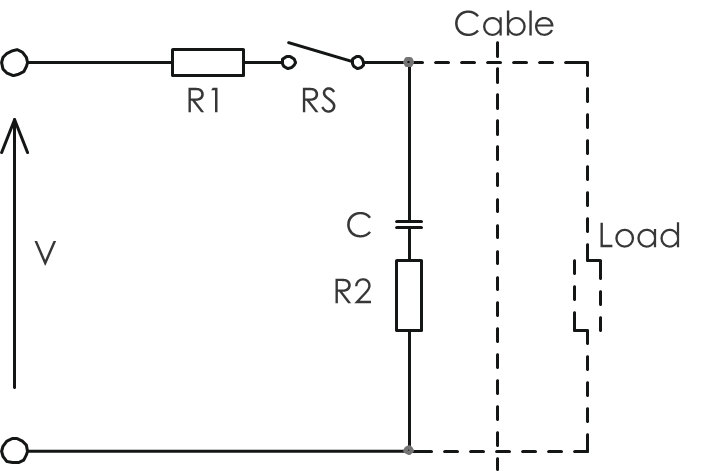

Unlike inductive loads, capacitive and lamp loads are prone to high in-rush currents which can lead to faulty operation and even contact welding.

When switching charged capacitors (including cable capacitance) a sudden unloading can occur, the intensity of which is determined by the capacity and length of the connecting leads to the switch.

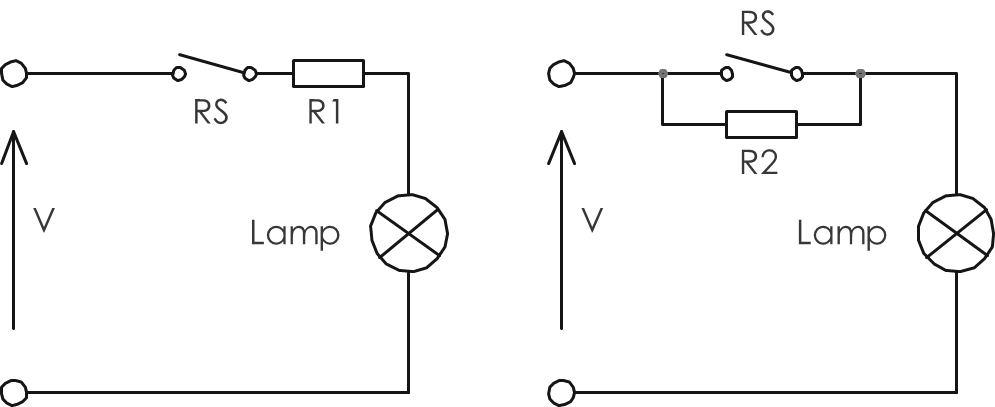

This in-rush peak can be reduced by a series of resistors. The value of these resistors is dependent on the particular application but should be as high as possible to ensure that the in-rush current is within the allowable limits.

With lamp load applications it is important to note that cold lamp filaments have a resistance 10 times smaller than already glowing filaments. This means that when being turned on, the lamp filament experiences a current flow 10 times greater than when already glowing. This high in-rush current can be reduced to an acceptable level through the use of a series of current-limiting resistors. Another possibility is the parallel switching of a resistor across the switch. This allows just enough current to flow to the filament to keep it warm, yet not enough to make it glow.

Different Forms of Reed Switches

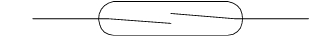

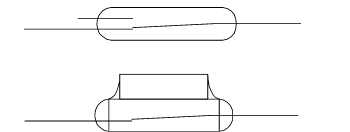

Normally open, Reed Switch will close contact in presence of a magnet.

Normally closed. Either achieved by using a Form C switch with the NO wire cut off or by using an attached magnet (requires pole oriented actuation).

Change over, Reed Switch will change from NC to NO contact in presence of a magnet.

Latching type. Switching status remains stable after a magnetic field disappears until a magnet with opposite polarity approaches.

The materials

The materials used for reed switch magnets are generally ALNICO (an aluminium nickel cobalt alloy), a ceramic (barium ferrite or another metal oxide) or rare earth magnets. Due to their specific magnetic characteristics, the types of magnets differ in shape: ALNICO magnets are bar magnets with a length/diameter ratio of 3/1 to 5/1; oxide magnets are generally disc or moulded magnets.

Also important to note is the difference in temperature coefficient: ALNICO: 0.02 %/K, oxide: 0.2 %/K.

Actuation of Reed Switches with a permanent magnet

Bellow are some examples of switching with the use of a moving magnet:

-

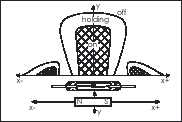

Direct actuation:

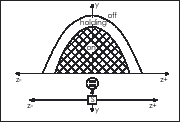

A magnet moved perpendicularly towards and away from a Reed Switch turns it off and on one time.

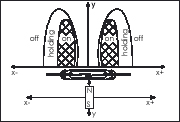

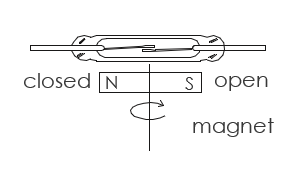

A magnet moved parallel to a Reed Switch operates it from one to three times.

A magnet moved parallel to a Reed Switch operates it from one to three times.

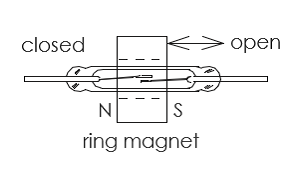

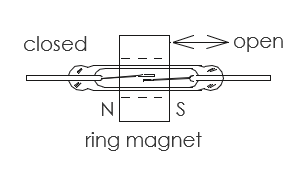

A ring magnet moved parallel to a Reed Switches axis operates it from one to three times.

A ring magnet moved parallel to a Reed Switches axis operates it from one to three times.

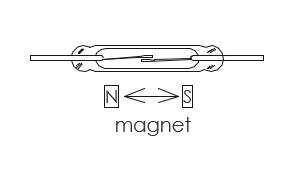

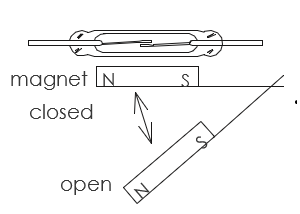

A magnet swung towards and away from a Reed Switch axis operates it one time.

A magnet swung towards and away from a Reed Switch axis operates it one time.

-

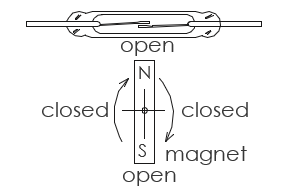

Rotation:

Examples of switching through arotational movement:

-

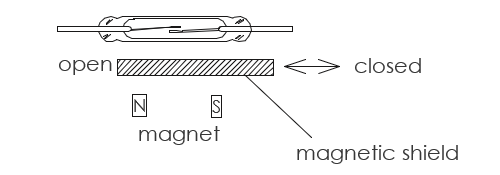

Indirect actuation with shielding:

With the stationary arrangement of a Reed Switch and magnet, the contact blades are closed. Should the magnetic field be diverted away from the Reed Switch by a shield of ferro-magnetic material placed between the switch and the magnet, the contacts will open. When the shield is removed, the contact blades become magnetically actuated and close.

Reed Switch advantages

- No power supply required

- Contacts hermetically sealed

- Most economic non-touch switching solution

- Not ESD sensitive

- Various methods of actuation possible

- Magnetic and electrical pole independent

- Non-touch actuation permits smooth surfaces and modern design

- Various sensitivity ranges available

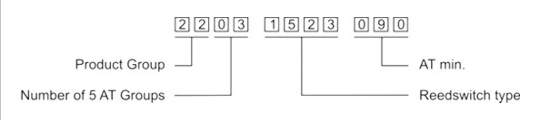

Order example

2203.1523.090 is an 1523 ReedSwitch, with pull-in sensitivity between 90-105AT (90+3*5AT);

2201.1917.065 is an 1917 Reed Switch, with pull-in sensitivity between 65-70AT (65+1*5AT).

Modified Reed Switch Solutions

Contact us if your application demands a tailor made Reed Switch solution, as all variations can be customized in order to meet customer requirements.