Magnetic Proximity Sensors

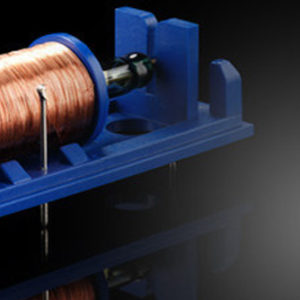

Proximity sensing is the technique of detecting the presence or absence of an object using a critical distance. Magnetic proximity sensors (MPS) are non-contact proximity devices which detect magnetic objects (e.g. permanent magnets).

MPS have established themselves within the market as the go-to solution where physical contact must be avoided. They are used wherever mechanical limit switches are not suitable due to unfavourable operating conditions or when other non-contacting switches such as inductive or capacitive sensors would be too expensive.

MPS are used for non-contact position detection beyond the normal limits of inductive sensors. In conjunction with a separate “damping” magnet, magnetic sensors offer very long sensing ranges from a small package size and can detect magnets through walls of non-ferrous metal, plastic or wood.

Depending on the orientation of the magnetic field, the sensor is damped from the front or from the side. In the food industry, the magnetic sensor is used in connection with a cleaning devices which passes through the inside of pipes.

Features of Magnetic Proximity Sensors

- Non-contact position detection beyond the normal limits of inductive sensors

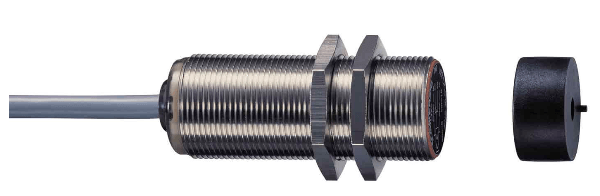

- Small housings with very long sensing ranges (up to 70 mm)

- Detection through walls of plastic, wood, and any non-magnetisable metals

- High mechanical stability in case of shock or vibration

- Cylinder and rectangular designs satisfy space-dependent applications

Advantages of Magnetic Proximity Sensors

- Contacts are well protected against dust, oxidation and corrosion due to the hermetic glass bulb and inert gas

- Contacts are activated by means of a magnetic field rather than mechanical parts

- Special surface treatment of contacts assures long contact life

- Maintenance free

- Easy operation

- Reduced size

Applications of Magnetic Proximity Sensors

Magnetic sensors are used in many industrial applications for contactless current sensing, linear and angular position, and rotation sensing. Magnetic sensors are designed to provide superior performance in all of these applications.

Magnetic Sensors for Power Distribution Unit (PDU)The PDU is a critical part of the data center infrastructure. PDU equipment is used to supply AC or DC electrical power to servers. Typically, the PDU provides power filtering and intelligent load balancing together with remote monitoring.

Robotics and Factory AutomationIn factory automation, both linear and angular position sensing are imperative to carry out complex motor movements with high precision, repeatability and accuracy. With the need for faster more efficient production lines, magnetic sensors are also used for linear and angular sensing, safety switches, and proximity detection.

Large home appliancesNew regulatory requirements for energy and water conservation in appliances can be accomplish through additional intelligent sensing. Magnetic sensors provide the added intelligence for open/close door detection, fluid level, and contactless current sensing.

Used in Green EnergyWhen it comes to alternative energy such as with wind and solar, magnetic sensors provide contactless current sensing, angular position sensing and switches. For wind power, the angular position sensing allows for optimal wind power generation, while contactless current sensors provide solutions for power inverters and solar combiner boxes. Switches can also assist with safety applications in high voltage environments.